When a leading petrochemical plant in Gujarat faced recurring failures with traditional support structures in their high-temperature processing units, they switched to ceramic grid blocks for heavy-duty industrial applications. Within six months of installation, the plant reported zero structural failures, improved thermal efficiency by 18%, and extended equipment lifespan by over five years. This real-world success story demonstrates why industrial ceramic grid blocks have become the preferred choice for demanding industrial environments where conventional materials simply cannot perform.

Ceramic grid blocks represent a critical advancement in industrial infrastructure, offering unmatched durability, thermal resistance, and load-bearing capacity. These specialized high-strength ceramic materials serve as essential support systems in power plants, chemical processing facilities, steel mills, and other harsh industrial environments.

Understanding Industrial Ceramic Grid Blocks

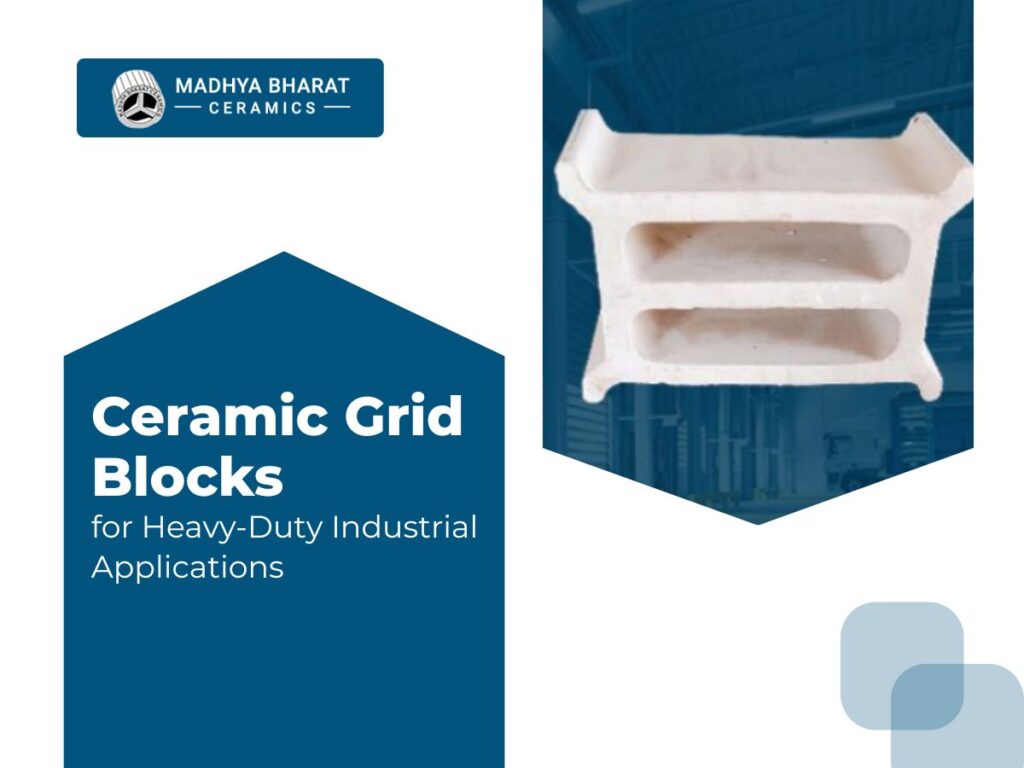

Ceramic grid blocks are engineered ceramic structures designed to provide stable support platforms in high-temperature industrial equipment. These load-bearing ceramic blocks function as foundational elements within furnaces, reactors, kilns, and other thermal processing units.

Unlike conventional support materials, industrial ceramic support systems maintain structural integrity at temperatures exceeding 1500°C. Their unique lattice design allows for optimal thermal distribution while supporting substantial weight loads from catalysts, aggregates, or other processing materials.

The manufacturing process involves carefully selected raw materials, precise molding techniques, and controlled high-temperature firing. This results in heavy-duty ceramic structures with exceptional mechanical strength, thermal shock resistance, and chemical inertness.

Key Properties of Ceramic Grid Blocks

1. Superior Thermal Resistance

The primary advantage of ceramic grid blocks for heavy-duty industrial applications lies in their remarkable thermal stability. These materials withstand continuous exposure to extreme temperatures without degradation, warping, or structural compromise.

High alumina content typically ranging from 60% to 99% ensures excellent refractory properties. This composition allows high alumina ceramic grid blocks for industries to maintain performance in environments where metal supports would melt and concrete would crumble.

2. Exceptional Load-Bearing Capacity

Load-bearing ceramic blocks are engineered to support significant weight while maintaining structural integrity. The grid design distributes loads evenly across the structure, preventing stress concentration points that could lead to failure.

Compressive strength values often exceed 100 MPa, making these blocks suitable for supporting heavy catalyst beds and packed columns. The cellular structure provides strength without unnecessary bulk, optimizing both performance and installation efficiency.

3. Chemical Resistance and Durability

Industrial environments frequently involve exposure to corrosive chemicals, acidic gases, and alkaline substances. Industrial ceramic grid blocks exhibit remarkable chemical inertness, resisting degradation from most acids, bases, and solvents.

This chemical stability ensures long service life even in aggressive environments. Power plants, refineries, and chemical processing facilities benefit from reduced maintenance costs and fewer unplanned shutdowns.

4. Thermal Shock Resistance

Rapid temperature fluctuations challenge most materials, causing thermal stress and potential cracking. Ceramic grid blocks are specifically engineered to withstand thermal cycling without structural damage.

The low thermal expansion coefficient and optimized microstructure allow these materials to accommodate temperature changes that would destroy conventional support systems. This property proves essential in processes involving frequent startup and shutdown cycles.

Primary Industrial Applications

1. Power Generation Plants

Ceramic grid blocks for chemical and power plants play crucial roles in boiler systems, heat recovery units, and emission control equipment. These blocks support catalyst beds in SCR (Selective Catalytic Reduction) systems that reduce nitrogen oxide emissions.

Power plants worldwide rely on these industrial ceramic support systems to maintain operational efficiency and environmental compliance. The combination of thermal resistance and structural stability makes them ideal for continuous operation environments.

2. Chemical Processing Facilities

Chemical reactors, distillation columns, and absorption towers require robust internal support structures. High alumina ceramic grid blocks provide stable platforms for packing materials and catalysts while resisting chemical attack from process streams.

Manufacturers of sulfuric acid, petrochemicals, and specialty chemicals depend on ceramic grid block supplier networks to maintain operational continuity. The inert nature of ceramic materials prevents contamination of products and ensures process purity.

3. Steel and Metal Production

Steel mills utilize heavy-duty ceramic structures in blast furnaces, ladle preheaters, and various thermal treatment equipment. The blocks support refractory linings and distribute heat evenly throughout processing chambers.

High alumina content provides the necessary refractoriness for molten metal environments. Ceramic grid block manufacturers serving the metallurgical industry focus on maximum temperature resistance and mechanical strength.

4. Petroleum Refining Operations

Refinery processes including catalytic cracking, reforming, and hydroprocessing employ ceramic grid blocks for load-bearing structures within reactor vessels. These blocks must withstand both high temperatures and exposure to various petroleum fractions.

The stability of industrial ceramic grid blocks ensures consistent catalyst support and prevents channeling that could reduce process efficiency. Refineries worldwide specify these materials for critical support applications.

Types and Specifications

1. High Alumina Ceramic Grid Blocks

High alumina ceramic grid block variants contain 60% to 99% aluminum oxide, offering superior performance for the most demanding applications. Higher alumina content correlates with increased refractoriness, mechanical strength, and chemical resistance.

These premium materials serve applications where maximum performance justifies the higher cost. Industries requiring continuous operation at extreme temperatures specify high alumina formulations for critical support systems.

2. Standard Industrial Grade Blocks

For moderate temperature applications (up to 1200°C), standard industrial grid block ceramics provide excellent performance at competitive pricing. These formulations balance thermal properties with economic considerations.

Many chemical processing and power generation applications operate within temperature ranges where standard grades deliver reliable long-term performance. Ceramic grid block exporter companies offer various standard grades to meet diverse industrial requirements.

Selection Criteria for Industrial Applications

Choosing the right ceramic grid blocks requires careful evaluation of several critical factors:

Temperature Requirements

- Identify maximum continuous operating temperature

- Add 100°C safety margin above maximum process conditions

- Consider thermal cycling during startup and shutdown

- Account for transient conditions and process upsets

Load Calculations

- Determine total weight of supported materials

- Include safety factors for potential overloading

- Verify compressive strength ratings match requirements

- Consult with ceramic grid block suppliers for capacity verification

Chemical Environment Assessment

- Analyze process stream composition and pH levels

- Identify oxidizing or reducing conditions present

- Review presence of corrosive compounds

- Select formulations with proven resistance to anticipated exposures

Installation Considerations

- Evaluate equipment access for installation and replacement

- Consider block dimensions, weight, and handling requirements

- Standardized sizes simplify sourcing and reduce lead times

- Custom dimensions may be necessary for retrofitting

Installation and Maintenance Best Practices

1. Pre-Installation Inspection

Examine all ceramic grid blocks for heavy-duty industrial applications for damage during shipping. Check dimensions against specifications and verify grid patterns match design requirements.

Inspect support surfaces within equipment to ensure they are clean, level, and free from debris. Proper foundation preparation prevents uneven loading and premature failure.

2. Installation Procedures

Follow manufacturer guidelines for block placement and alignment. Maintain consistent spacing between blocks to allow thermal expansion without constraint.

Use appropriate lifting equipment to prevent impact damage. Heavy-duty ceramic structures are strong in compression but vulnerable to impact and bending stresses during handling.

3. Operational Monitoring

Implement regular inspection schedules during planned maintenance shutdowns. Look for signs of cracking, displacement, or degradation that might indicate problems.

Monitor process conditions for excursions beyond design parameters. Temperature spikes or chemical upsets can damage industrial ceramic grid blocks even when they meet normal specifications.

Quality Standards and Certifications

Reputable ceramic grid block manufacturer companies maintain quality management systems certified to ISO 9001 standards. This ensures consistent production processes and reliable product quality.

Material testing should verify key properties:

- Bulk density and apparent porosity

- Cold crushing strength

- Refractoriness under load

- Thermal expansion characteristics

- Chemical composition analysis

Request test certificates documenting compliance with specifications. Quality assurance reduces risk of premature failure and ensures reliable long-term performance.

Sourcing from Manufacturers

1. Selecting a Manufacturer

Choose manufacturers with proven experience in your specific industry. Review case studies and reference installations demonstrating successful applications similar to yours.

Ceramic grid block manufacturers in India have established strong global reputations for quality products at competitive prices. Many offer technical support services to assist with product selection and application engineering.

2. Working with Suppliers

Establish relationships with suppliers who understand your technical requirements and can provide reliable delivery. Consistent quality and on-time delivery prove essential for maintenance planning.

Request technical data sheets, installation guidelines, and application support. Experienced ceramic grid block supplier teams help optimize specifications for your particular needs.

Cost Considerations and ROI

Initial costs for high-strength ceramic materials exceed conventional support options, but total lifecycle economics favor ceramic solutions. Extended service life, reduced maintenance frequency, and improved process reliability deliver substantial returns.

Calculate total cost of ownership including:

- Initial material and installation costs

- Expected service life versus alternatives

- Maintenance and replacement labor

- Production losses during maintenance shutdowns

- Energy efficiency improvements from better thermal management

Most industrial facilities find that ceramic grid blocks for load-bearing structures pay for themselves within the first replacement cycle compared to conventional materials.

FAQ’s About Ceramic Grid Blocks

1. What are ceramic grid blocks used for in industries?

Ceramic grid blocks provide structural support in high-temperature equipment like furnaces, reactors, and boilers withstanding extreme heat conditions.

2. Which industries commonly use industrial ceramic grid blocks?

Power generation, chemical processing, petroleum refining, steel production, and cement manufacturing rely on industrial ceramic grid blocks extensively.

3. What temperature range can ceramic grid blocks withstand?

High alumina ceramic grid blocks typically withstand continuous temperatures from 1200°C to over 1700°C depending on composition.

4. How long do ceramic grid blocks last?

Service life varies by application severity but load-bearing ceramic blocks typically last five to fifteen years properly.

5. What advantages do ceramic blocks offer over metal?

Ceramic grid blocks offer superior temperature resistance, chemical inertness, no corrosion, and stability where metals melt.

6. Can I get custom ceramic grid block designs?

Yes, leading ceramic grid block manufacturer companies offer custom dimensions, grid patterns, and compositions for specific applications.

Conclusion

Ceramic grid blocks for heavy-duty industrial applications have revolutionized how industries approach high-temperature support systems and load-bearing requirements. These engineered industrial ceramic grid blocks deliver unmatched performance in environments where traditional materials simply cannot survive, making them indispensable components in modern industrial operations.

The success story of the Gujarat petrochemical plant exemplifies the transformative impact these materials can have on operational efficiency, safety, and long-term cost savings. By switching to ceramic grid blocks, industries worldwide are experiencing fewer equipment failures, reduced maintenance downtime, and significant improvements in process reliability.